How Routine Testing and Refurbishment Extend Electrical Equipment Lifespan

Learn how routine testing and refurbishment can extend the lifespan of electrical equipment, improve safety, and ensure reliable performance.

Routine inspections, performance assessments, and targeted refurbishments are key to identifying critical issues before they become costly emergencies. Investing in proactive care assures compliance with industry benchmarks, saving time and operational resources while reducing the environmental footprint associated with frequent equipment replacement. Organizations looking to maximize uptime and asset productivity rely on partners with a strong track record of electrical equipment testing and refurbishment services.

Maintaining the reliability and efficiency of electrical equipment is vital for safety, operational excellence, and minimizing costs tied to unexpected failures. One proven way organizations accomplish this is through regular testing and refurbishment—practices that boost equipment integrity and ensure a safer work environment and prolonged asset longevity. Experienced service providers such as Divergent Alliance electrical equipment testing make this process accessible and effective with modern solutions and expert support.

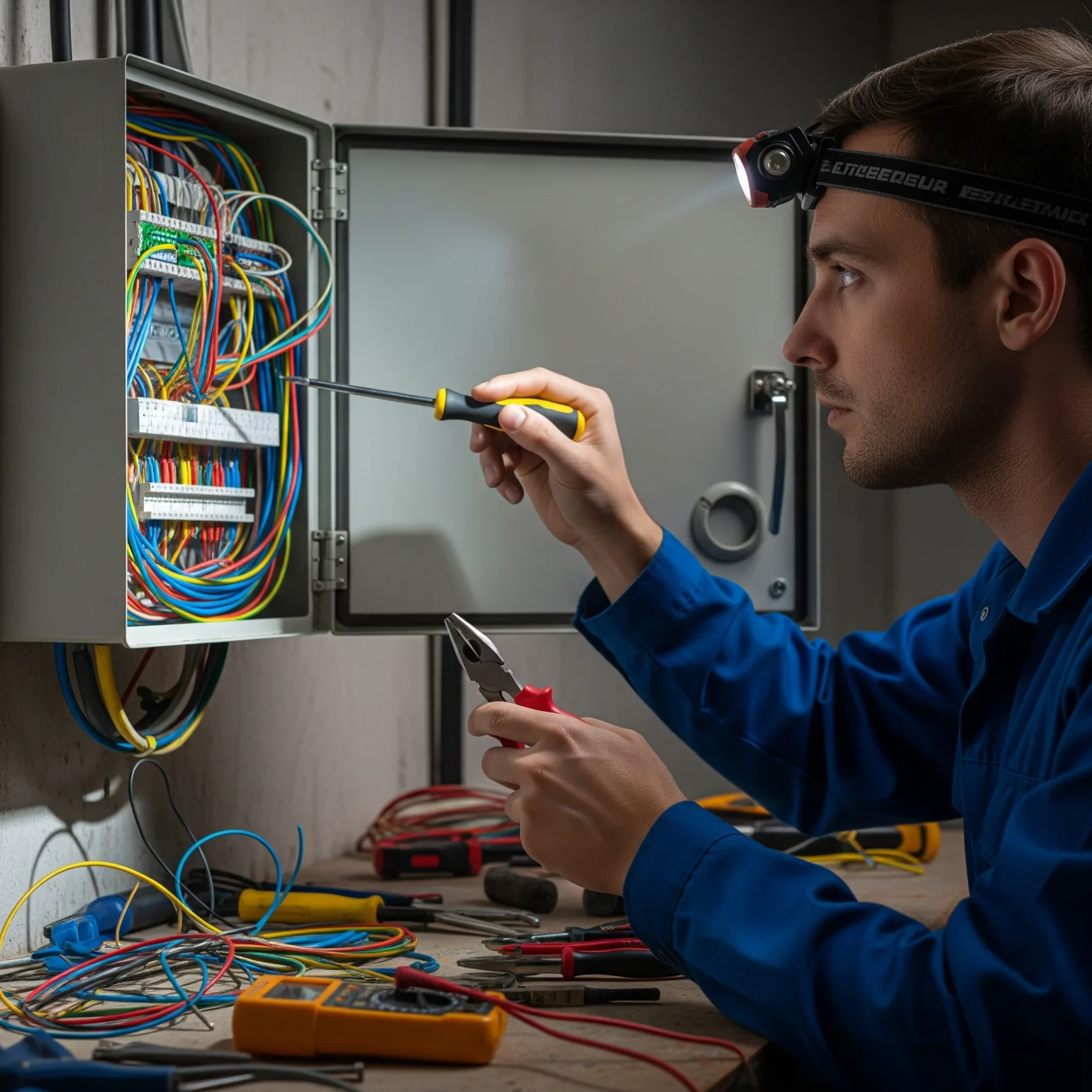

Importance of Regular Testing

Routine testing of electrical systems helps expose underlying faults—such as deteriorating insulation, loose connections, or faulty breakers—that could escalate into hazardous incidents or operational disruptions. The U.S. Occupational Safety and Health Administration (OSHA) recognizes electrical failures as a leading source of workplace injuries, making regular inspections critical for organizations seeking compliance and prevention. For high-risk sectors like manufacturing, utilities, or healthcare, scheduled equipment assessments are indispensable in guarding assets and lives.

Benefits of Equipment Refurbishment

Refurbishing electrical assets extends their operational lifespan, improves performance, and supports green initiatives. It reduces environmental impact by minimizing waste and conserving resources. Refurbishment is often more affordable than replacement and can enhance capacity, incorporate new safeguards, and accommodate evolving standards while keeping legacy equipment functional.

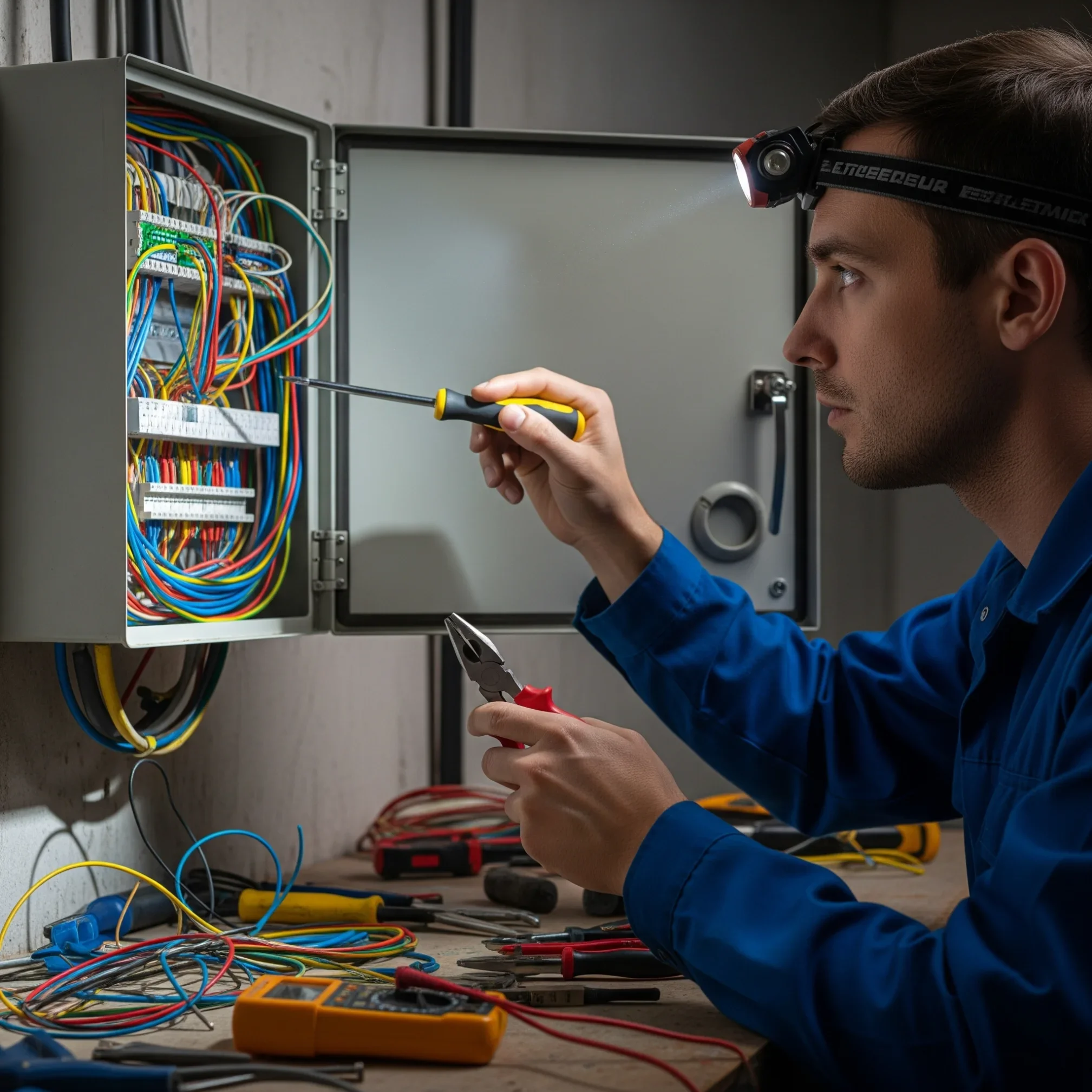

Preventive Maintenance Strategies

Preventive maintenance involves regular inspections, performance checks, and repairs to prevent downtime in electrical assets. Strategies include visual checks, diagnostic tests, component replacement, and environmental management. This proactive approach enhances equipment reliability and improves workplace safety and long-term ROI, ensuring equipment longevity.

Compliance with Industry Standards

Industry standards set forth by organizations such as the International Electrotechnical Commission (IEC) and the National Fire Protection Association (NFPA) provide safe and efficient equipment maintenance benchmarks. Adherence to these guidelines demonstrates a company’s commitment to best practices, reducing liability, and boosting trust among clients and regulatory bodies. Regular audits, documentation, and practice reviews are foundational to sustaining compliance and profiting from safer, more dependable operations.

Cost-Effectiveness of Maintenance Programs

Though preventive maintenance and refurbishment require ongoing investment, they offer considerable long-term savings by reducing emergency repairs, minimizing production losses, and extending capital equipment life cycles. For example, as reported by ABB, businesses with comprehensive maintenance programs enjoy higher productivity, lower risk of unplanned outages, and greater overall asset value. Ignoring regular servicing can result in costly outages, loss of productivity, and reputation damage that far outweigh initial savings from neglecting maintenance.

Implementing a Maintenance Schedule

A robust maintenance schedule is crucial for equipment reliability and efficiency. This schedule involves a condition assessment, detailed planning, consistent execution, and performance review. This cycle maximizes asset return, creating a culture of high performance and risk mitigation. Regular documentation and reporting ensure timely task completion, ensuring optimal equipment performance.

Conclusion

Regular testing and refurbishment are pillars of responsible equipment management. Organizations that prioritize these practices realize measurable benefits: reduced downtime, increased asset longevity, regulatory compliance, and substantial cost savings. With trusted partners, businesses can achieve their operational goals while supporting a safety and sustainability culture. Implementing a structured maintenance program is not just wise but essential for long-term growth and industry leadership.